04

Occupational health and safety

GRI 2-12, 2-13

Contribution to the UN SDGs

Key performance indicators for 2024

0

Lost Time Injury Frequency Rate (LTIFR)

0

Fatal Accident Rate (FAR)

0

Number of fires

0

Number of accidents

0

Number of road traffic accidents

3.078

billion tenge

Occupational health and safety expenditures

99.99987%

General availability level of systems (GA)

Key documents on occupational health and safety

- Development Plan for 2023–2032

- Guide to the Sustainable Development Management System

- Occupational Health and Safety Policy

- Objectives for Quality, Environment, Occupational Safety and Health

- Hazard and Risk Register

- Occupational Health and Safety Management System Manual

- Occupational Safety and Health Management Planning Standard

- Behavioural Audit Standard

- Safety Management Standard for Work Performed by Contractors

- Rules for Incident and Accident Investigation and Reporting on Occupational Health and Safety

- Occupational Safety Rules for Working at Heights

GRI 2-24, 403-1, 403-8

KEGOC JSC regards occupational safety and the health of employees as an unconditional priority. The Company systematically works to create safe working conditions, reduce occupational injuries, improve sanitary and welfare conditions, and minimise the impact of harmful factors on employees.

The Company has implemented and successfully operates the Occupational Health and Safety Management System (OHSMS) based on ISO 45001, which is an integral part of the Company’s integrated management system and applies to the activities of all structural subdivisions and subsidiaries of the Company and its contractors. The scope of application of the OHSMS is to perform the functions of a system operator in the electric power industry: provision of system services to wholesale electricity market entities for the transmission of electricity through the national electricity network, technical dispatching and organization of balancing of electricity production and consumption.

In order to confirm KEGOC JSC’s compliance with the OHSMS, a certification audit was conducted in 2023 by “MS CERTIFICATION SERVICES PRIVATE LIMITED” (India), an independent certification body, and in 2024 — a supervisory audit, which confirmed the compliance of the OHSMS with the requirements of international standards.

Every year, a program in the field of occupational health and safety is formed, which determines the necessary measures, costs and deadlines for their implementation. The Company has successfully implemented and passed certification for compliance with the international standard ISO 45001:2018.

GRI 403-3

In accordance with the laws of the Republic of Kazakhstan, the Company provides mandatory insurance for employees against accidents related to the performance of their work (official) duties. Additionally, 24/7 life and health accident insurance not related to professional activity is provided, as well as voluntary health insurance in case of illness — all aimed at enhancing the social protection of employees.

Each branch of the Company has established Occupational Health and Safety Services. These services are responsible for organising and implementing technical and organisational measures on occupational health and safety, conducting internal OHS control, and monitoring compliance with regulatory legal acts on health and safety by employees.

GRI 403-2, 403-3, 403-4

To ensure effective dialogue between employees and the employer in the field of occupational safety, production safety councils have been established in KEGOC JSC and its branches. These councils operate on a parity basis with the participation of both parties and are aimed at consolidating efforts to ensure safe working conditions and health protection in the workplace.

Designated technical inspectors participate in regular inspections of working conditions, safety, and occupational health. All Company employees not only have the obligation but also the right to suspend work upon identifying potentially hazardous conditions or actions. The Company’s management fully supports employees in their decisions to stop unsafe work.

At least once per quarter, the production safety councils consider employee proposals to improve working conditions and safety. As a result, mandatory measures are developed to be implemented by both the employer and employees.

Risk assessment

GRI 403-2, 403-7, 403-10

KEGOC JSC conducts annual identification and assessment of occupational risks at workplaces. Based on the results, a risk register is compiled, including a list of significant occupational health and safety risks, and measures are developed to mitigate them.

Risk analysis is carried out considering both the likelihood of occurrence and potential consequences. Key risks that may negatively impact the Company’s operations and the achievement of its strategic goals are identified. Depending on the nature of the risks, qualitative, quantitative, or combined assessment methods are used.

Hazard and risk assessment and management are performed to establish occupational health and safety management objectives and to achieve an acceptable level of impact of production and business operations on the environment and employees of KEGOC JSC.

The results of hazard and risk assessment and analysis serve as input for the development of performance indicators and targets. Hazard and risk assessment is conducted based on activity type and hazard classifiers applicable to KEGOC JSC operations, considering geographic location and climate. The process includes:

- identification of hazards and risks using classifiers;

- risk assessment with existing control measures in place;

- determination of all additional necessary risk control measures;

- evaluation of whether current control measures are sufficient to reduce the risk to an acceptable level.

Following the identification of exposure factors affecting the workplaces of structural units, a risk register is compiled using the FMEA method. Based on the assessment results, lists of significant occupational health and safety risks across KEGOC JSC are formed. To reduce the risk level, required mitigation measures are defined and formalised in annual programmes.

One of the key risks to the Company’s operations is the risk of occupational accidents.

To minimise this risk, the following measures were implemented in 2024:

- qualification assessments on occupational and industrial safety regulations;

- analysis of video footage of operational switching and maintenance work processes;

- Safety days;

- unscheduled workplace inspections at MES branches;

- behavioral safety audits during on-site work;

- Monitoring of speed limit compliance by drivers via satellite tracking systems and dashcam recordings; and more.

Company employees undergo all mandatory occupational health and safety training, including qualification checks on energy sector regulations, at least once every three years. In 2024, additional training was conducted on the international standard “NEBOSH International General Certificate in Occupational health and safety” and “Occupational safety culture”. The Company also participated in the “KIOSH 2024” occupational health and industrial safety conference.

GRI 403-5

Before being allowed to work, employees undergo training in safe working practices, on-the-job internships, initial qualification assessments, control drills, and job shadowing under the supervision of a designated trainer.

Training was also conducted on the use of fall protection harness systems for personal protection against falls from height. This training was provided to those responsible for safe work procedures among the personnel of overhead transmission line production units on the topic: “Use of fall arrest systems for personal protection against falls from height.”

GRI 403-2, 403-3, 403-6, 403-10

Mandatory pre-shift and post-shift medical examinations are conducted at the Company for employees engaged in hard physical labour or work in harmful and/or hazardous conditions, as well as pre-trip and post-trip medical checks for drivers. As part of its commitment to employee health and disease prevention, KEGOC JSC ensures that production personnel undergo annual medical examinations at healthcare facilities, in full compliance with medical confidentiality. This includes the protection of personal medical data, health status, diagnoses, and any other information obtained during the examination or treatment of employees, in accordance with the Code on public health and the health system of the Republic of Kazakhstan.

In 2024, no occupational diseases were recorded among KEGOC JSC employees, outstaffed personnel, or contractor employees.

Injuries

GRI 403-9, SASB IF-EU-320a.1

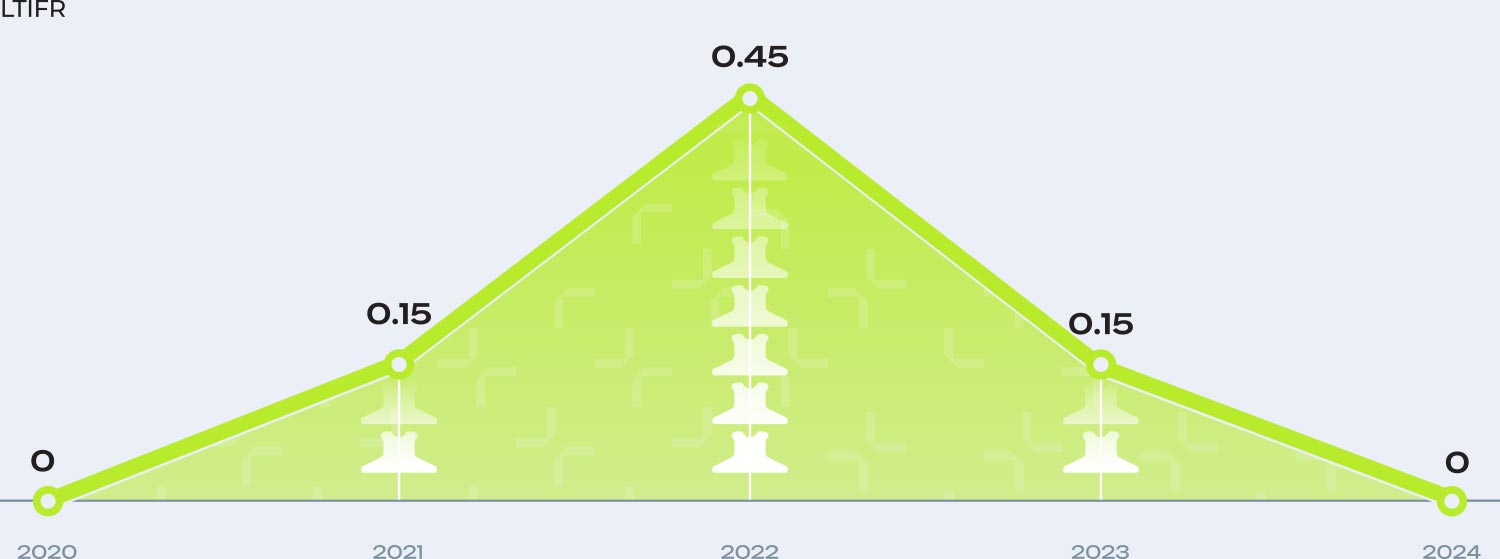

To assess the level of occupational safety at KEGOC JSC, the international LTIFR (Lost Time Injury Frequency Rate) indicator is used. This rate includes work-related fatalities (FAR) and reflects the number of lost time injuries (LTI) per one million hours worked. It serves as a key benchmark in international practice for evaluating the effectiveness of occupational and industrial safety management systems.

In 2024, the LTIFR was 0, with a total of 7,990,086 hours worked (compared to 0.13 in 2023; excluding Energoinform JSC — 0.15).

No work-related injuries were recorded during the reporting period.

Lost Time Injury Frequency Rate among KEGOC JSC employees (excluding Energoinform JSC)

GRI 403-2

In the event of incidents, KEGOC JSC employees follow established procedures that govern the investigation of incidents and accidents, as well as the reporting processes related to occupational health and safety.

The typical causes of work-related accidents in the Company’s operations include:

- falls from height;

- electric trauma;

- road traffic accidents.

Work with contracting organizations

GRI 403-5, 403-7, 403-8, 403-9, EU18

When work is performed at KEGOC JSC facilities by contractors and outstaffed organizations, the Company assumes responsibility for ensuring the safety of these workers. All work and service contracts include mandatory provisions requiring compliance with the legislation of the Republic of Kazakhstan and the Company’s internal occupational health and industrial safety regulations.

Prior to the commencement of work, orientation meetings are held with contractor representatives. All contractor personnel undergo introductory and job-specific briefings on occupational and fire safety. Targeted safety briefings are conducted daily, highlighting current hazardous and harmful production factors at Company sites. Engineering and technical personnel of contractor organizations also receive training under the “Occupational Safety Culture” course.

During work execution, internal monitoring of occupational safety requirements is carried out, including regular Behavioral Safety Audits (BSA) and performance evaluations of contractors in the area of occupational health and safety. All contractor and outstaffed personnel involved in work at KEGOC JSC production sites are fully covered by the Company’s occupational health and safety management system.

In 2024, no work-related injuries or fatalities were recorded among contractor or outstaffed workers at the Company’s facilities, with a total of 461,513 hours worked.