Reliability and development of NPG

03

Network reliability

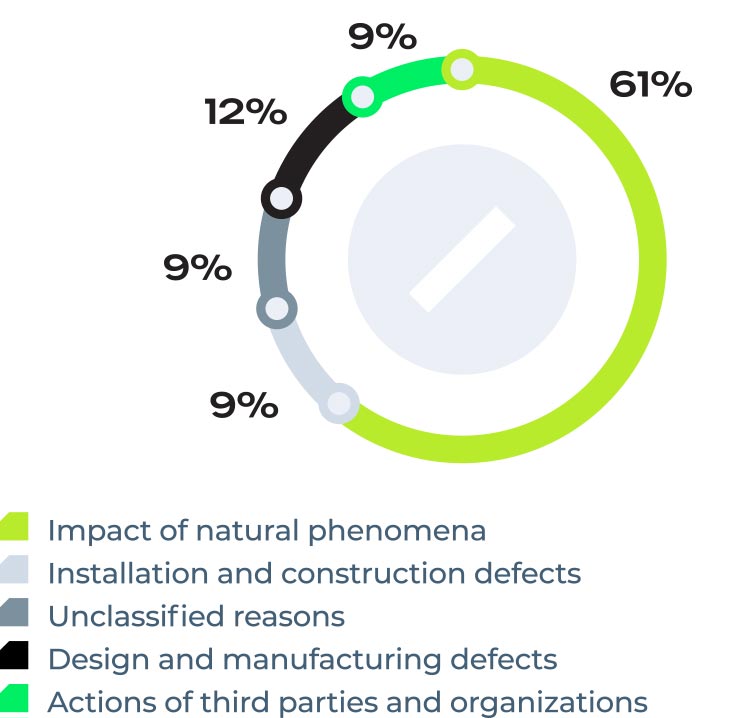

Distribution of technological violations by classification criteria

The electric power industry is important for the Republic of Kazakhstan, as the country’s key industries, such as metallurgy and oil and gas production, are characterized by high energy intensity. Accordingly, the competitiveness of the industry of the Republic of Kazakhstan and the quality of life of the population largely depend on reliable and high-quality energy supply to consumers.

In 2024, the Company recorded and investigated 43 technological violations, of which 1 failure of the 1st degree and 42 failures of the 2nd degree, including: 33 technological violations occurred on power transmission lines, 10 technological violations occurred at substations. There were no accidents. Compared to 2023, the indicator has improved by 34%.

The following indicators are used in international practice to assess the level of network reliability:

SAIDI (System Average Interruption Duration Index — characterizes the average duration of one system outage per year in minutes.

GRI EU29, SASB IF-EU-550a.2

SAIDI

SAIFI (System Average Interruption Frequency Index) — characterizes the average frequency of power supply interruptions to consumers.

GRI EU28, SASB IF-EU-550a.2

SAIFI

GRI 201-2

In 2024, 26 technological disruptions occurred due to the effects of natural phenomena (60% of the total number).

Climate change is causing an increasing number of serious and extreme weather events that pose a threat to the reliability of Company network facilities, including strong winds and rains, hail, hurricanes, cyclones, droughts, as well as the risks of fires and floods. Extreme weather conditions and changes in air temperature can lead to system strain, reduced efficiency, and possible disruptions in customer service for KEGOC JSC.

The main unfavorable climatic factors potentially leading to negative impacts are strong winds, lightning surges, formation and discharge of icy-frost deposits on overhead line wires and lightning lines.

The Company creates a Risk Register on an annual basis, which includes, among other things, climatic factors. During its formation, an analysis of potential scenarios that KEGOC JSC may face is carried out, including the variability of weather conditions, as well as an increase in the frequency and intensity of extreme climatic events. The possible consequences of these risks include:

- SS and PTL equipment failure;

- reduction in the volume/quality of electricity supplies to consumers;

- under-discharge of electricity;

- the occurrence of unforeseen expenses for the restoration of equipment.

KEGOC JSC performs climate risk management based on the Risk Register. One of the risks affecting the reliability of the Company’s network is the risk of “failure of production assets”, which may be caused by natural disasters. To minimize this risk, the Company takes the following measures:

- training of personnel in emergency recovery operations;

- ensuring the readiness of vehicles and special equipment for emergency recovery operations;

- staffing of branches with emergency stock;

- SS equipment insurance;

- conducting emergency training;

- development of proposals for the introduction of innovations to reduce the impact of natural phenomena on the Company’s production assets.

In addition, to ensure the reliability of the network in order to reduce the key risk of failure of production assets in 2024, the Company implemented:

- replacement of high-voltage inputs of power electrical equipment;

- technical inspection of SS and PTL equipment with the involvement of expert organizations;

- technical expertise of SS and PTL equipment with the involvement of expert organizations;

- modernization and reconstruction of assets;

- analysis of technological disruptions in electrical networks.

Emergency response

Climate change, namely natural factors (floods, hurricanes, earthquakes, epidemics), create the risk of emergency situations. To minimize this risk, the Company conducts emergency response training in accordance with the annual schedule according to approved topics; participates in the annual republican command and staff exercises “Koktem”, “Kys”, “Zher” where measures to eliminate the consequences of natural disasters (floods, hurricanes, earthquakes) are worked out, and also purchases personal protective equipment.

In order to ensure business continuity for the business process of uninterrupted production activities for the elimination of large-scale emergencies, KEGOC JSC has developed accident response plans (ARP) and an action plan for the elimination of emergencies (APEE) specific to the Company’s activities.

ARP establishes the object, scope and sequence of actions in case of an emergency, as well as responsibility for their provision and implementation. ARP testing is conducted in the form of regular fire and emergency training.

The APEE reflects the activities carried out in the event of a threat of occurrence and elimination of the consequences of an emergency, indicating the timing and time of work. The most common type of emergency at the Company’s facilities can be a fire due to non-compliance with fire-fighting measures and the occurrence of emergency situations. APEE also includes measures in case of a threat of terrorist acts that pose a risk of loss of life, significant property damage, or other serious consequences. For timely notification of the Company’s employees in the event of an emergency and its liquidation, Communication and Notification Plans and a Fire Extinguishing Plan, which are part of the APEE, are put into effect.

To check readiness for actions to eliminate possible emergencies, the Company participates in the annual republican command and staff exercises, conducts object training and seismic training in areas with a high risk of earthquakes (South, East, West). These exercises verify the completeness of the development of plans, the coherence of civil protection units, and the effectiveness of forces and means during emergency recovery operations at thermal power plants.

Achieving Strategic goal 1:

- Grid Аvailability (or Availability of the electric grid, measured in % for the reporting year);

- AIT (Average Interruption Time — average interruption time, in minutes).

By the end of 2024, KEGOC JSC planned strategic KPI’s have been achieved and exceeded.

Implementation of strategic KPI’s in 2024

| KPI name | 2020 (actual) | 2021 (actual) | 2022 (actual) | 2023 (actual) | 2024 (goal) | 2024 (actual) |

|---|---|---|---|---|---|---|

| GA, % | the indicators were determined in December 2021 | 99.99987 | 99.99988 | 99.99878 | 99.99987 | |

| AIT, min. | 0.682 | 0.657 | 6.411 | 0.671 | ||